Ever since I first started in electronics, I yearned for high tech fabrication tools! Over the last few years, theres been great strides in bringing CNC and 3d printing to the hobbyist market. As I got deeper into building music gear, I realized i'd either have to pay outrageous prices, or build some tooling to accomodate my prototyping needs. The former is pretty tough with kids, so build it is the flavor of the day. Besides, theres no greater feeling then building the tool to build the thing!

My Current Router

work area is about 2'x3', cutting area is something like 28x20

I've worked in wood, acrylic and some metals

Bosch Colt 1hp router

TB6560 4 axis controller

4 x nema 23 steppers

1/2-10 5 start leadscrews

DumpsterCNC couplers and AntiBacklash nuts

Thrust bearings on all axis

Prefabricated Z-Axis with 4 Inch travel from IMService

120VAC Solid State Relay

Aluminum / steel frame

Big Heavy MDF Enclosure

CNCRouterParts RP4848 for Growler Solutions

I built this machine for my friends wood shop. This thing is a BEAST! We put Nema23 520oz/in steppers on it and a 3hp Porter Cable router. It can easily do 200 inches / minute thru hardwood

Some of the things I've made

How NOT to build a CNC Router!

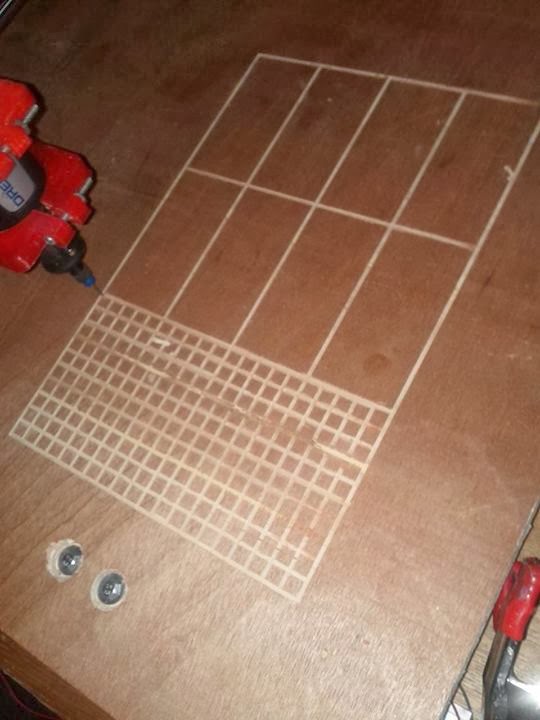

I started experimenting with recycled bits of dot matrix printers and scanners. I got a few steppers together and some very crude electronics. Put that together with an arduino and a dremel, and things are about to get REAL! It took alot of patience, and MANY fails, especially considering alot of it was made with hand tools and a battery drill!

I swear, I took apart the entire machine at least 10 times before I got what I've got now. Granted minor hardware changes required large design changes!

I started upgrading by getting a few sets of linear bearings and such. Some cheap nema-14's and a 3d printer controller with a broken heater port got "G-Code" sending to the machine and I was able to move a dremel around. 3d printed parts played a key role in the following developments

Moving Bed and Y Axis. 3d Printed parts in Red and Yellow for the drive connections. bad idea, lots of slop, etc. The nice thing is it did give me reasonable measurements and ways to mock it up as I went.. Notice how its all mounted on a coffee table? LOL

An example of a large 3d printing mockup I made. I designed it in sketchup and watched it print (poorly) for several hours. It actually was one of the more precise bits that I did, but it wasn't very solid (low infill on the print).

.jpg)

1 comment:

Dedicated Impex is leading gear cutting tools Manufacturers Company in India, we are manufacturers and suppliers of gear cutting tools, CNC router bits, keyway broaches, router bits and slotting cutters in all over India.

Gear Cutting Tools

Post a Comment